sheet metal drawing operation is used to make

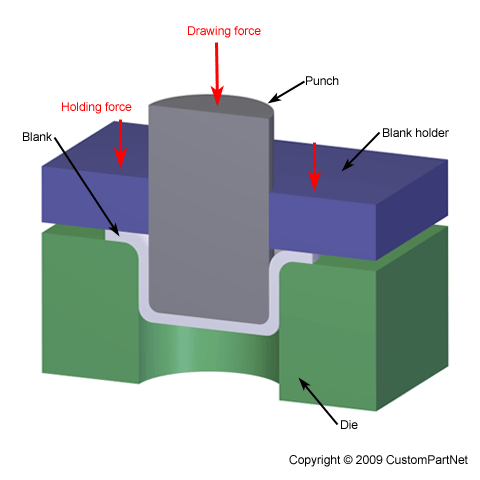

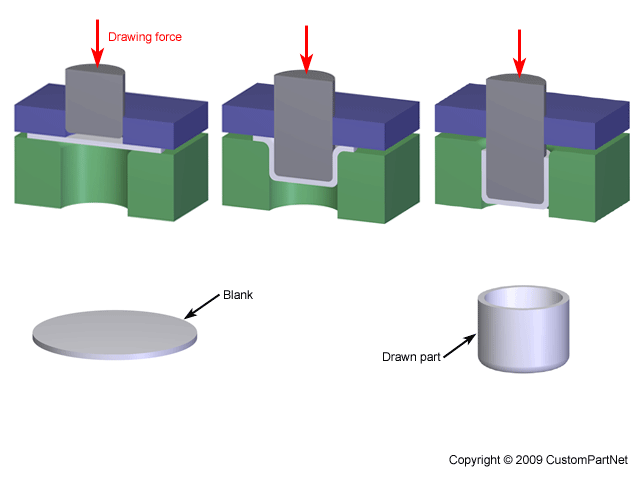

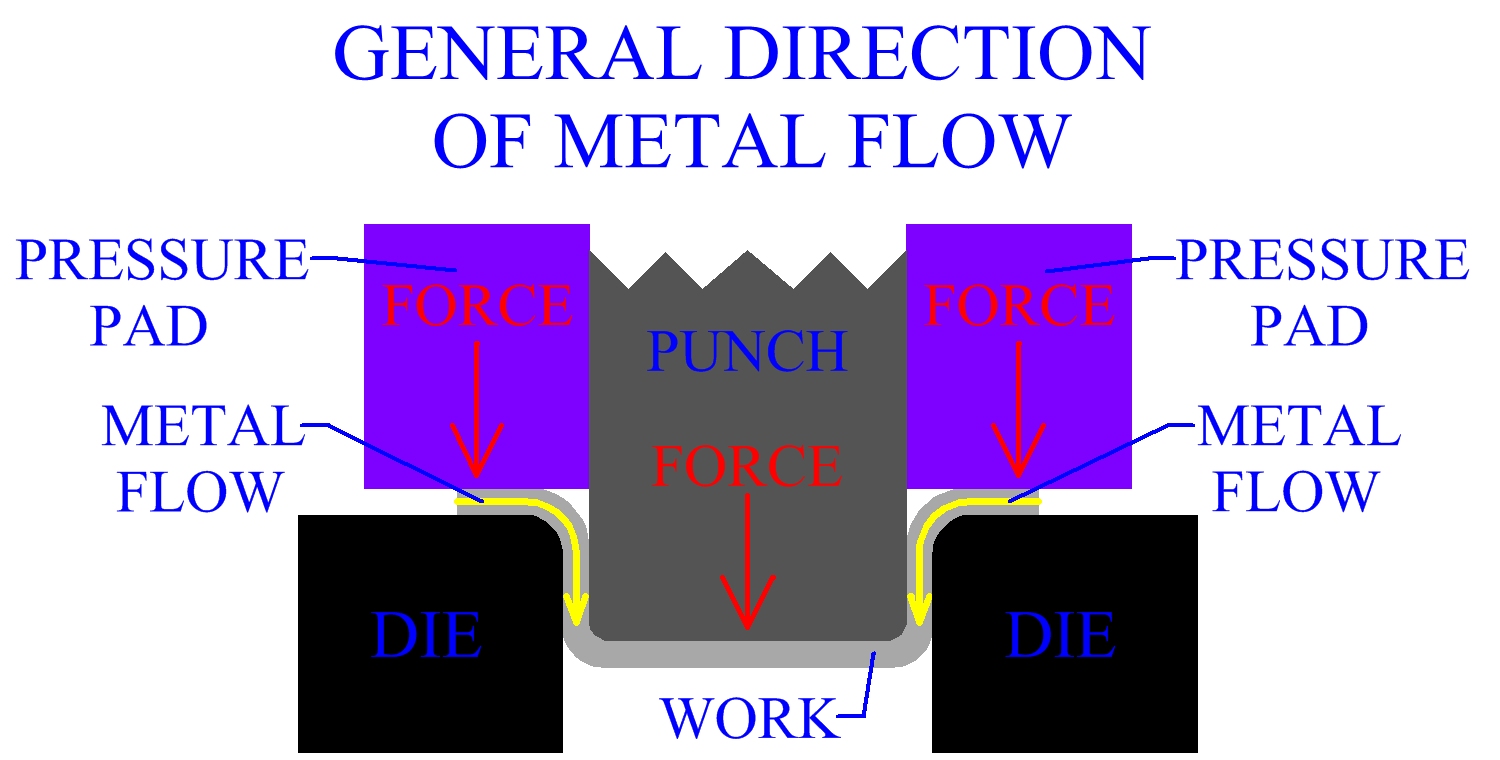

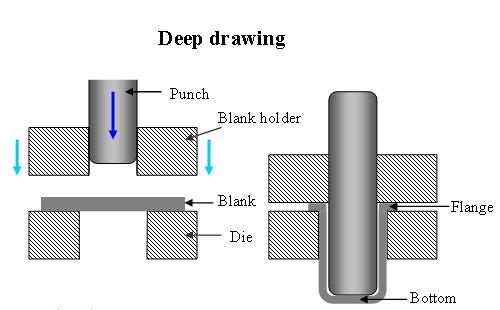

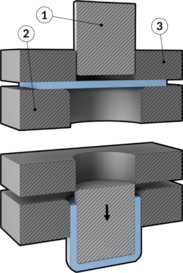

Deep drawing of sheet metal is performed with a punch and die. The pressure pad removes all the wrinkles meanwhile.

Deep Drawing An Overview Sciencedirect Topics

Cutting and forming thin sheets of metal usually performed as cold working Sheet metal 04 164 to 6 mm 14in thick Plate stock 6 mm thick Advantage - High strength good dimensional accuracy good surface finish economical mass production low cost.

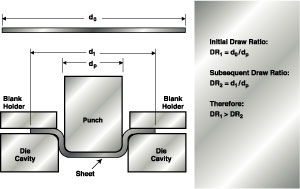

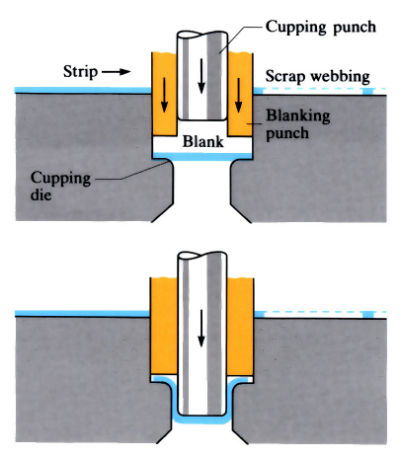

. Drawing is a metalworking process that uses tensile forces to stretch elongate metal glass or plasticAs the metal is drawn pulled it stretches to become thinner to achieve a desired shape and thickness. Deep drawing of sheet metal is performed with a punch and die. The die cavity matches the punch and is a little wider to allow for its passage as well as clearance.

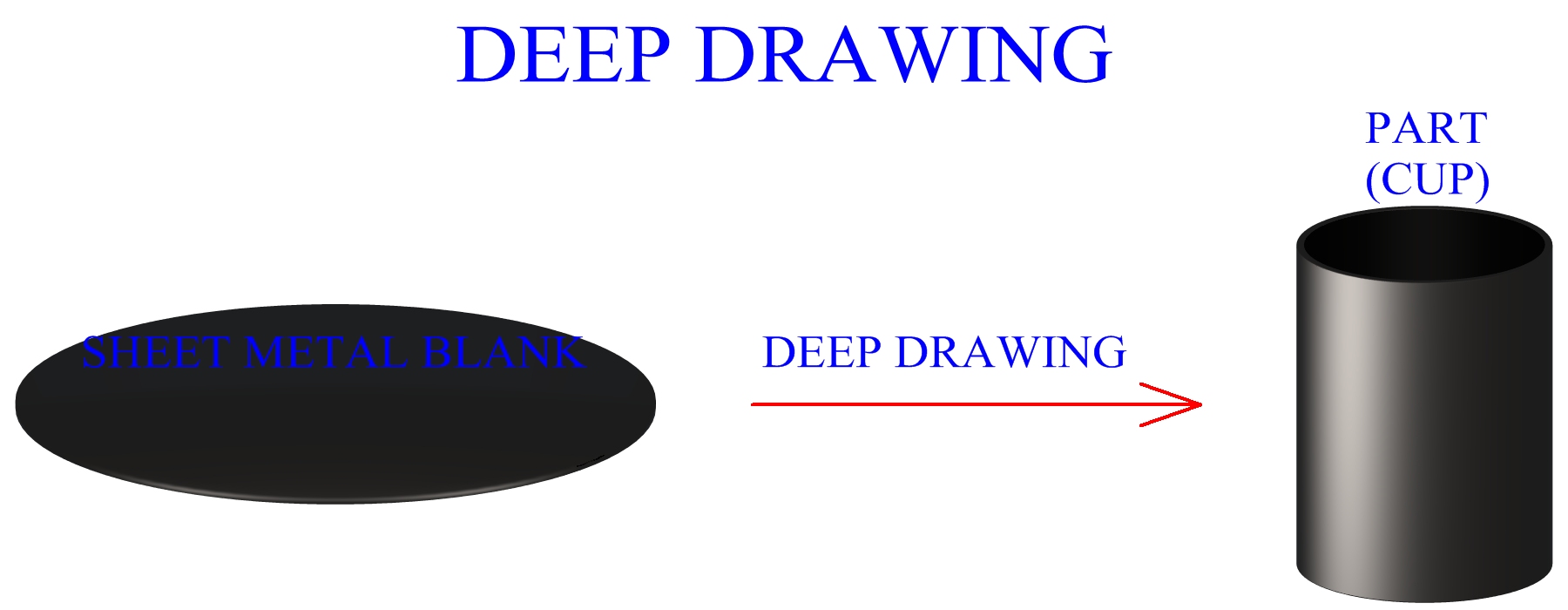

1 Deep drawing is the process of converting blank of sheet metal into a cylindrical containers with a flat or hemispherical base. In the operation the sheet metal is clamped. 2 It is combination of metal forming process sheet metal process.

Sheet metal forming is a. A Schematic illustration of the deep-drawing process on a circular sheet metal blank. Drawing Sheet metal forming operation used to make cup shaped box shaped or other complex curved hollow shaped parts Performed by placing a piece of sheet metal over a die cavity and then pushing the metal into the opening with a punch.

Answer 1 of 4. Following types of sheet metal bending methods are available according to sheet metal bend type bend shape and production volumes. The following are measures of feasibility for several proposed cup-drawing operations.

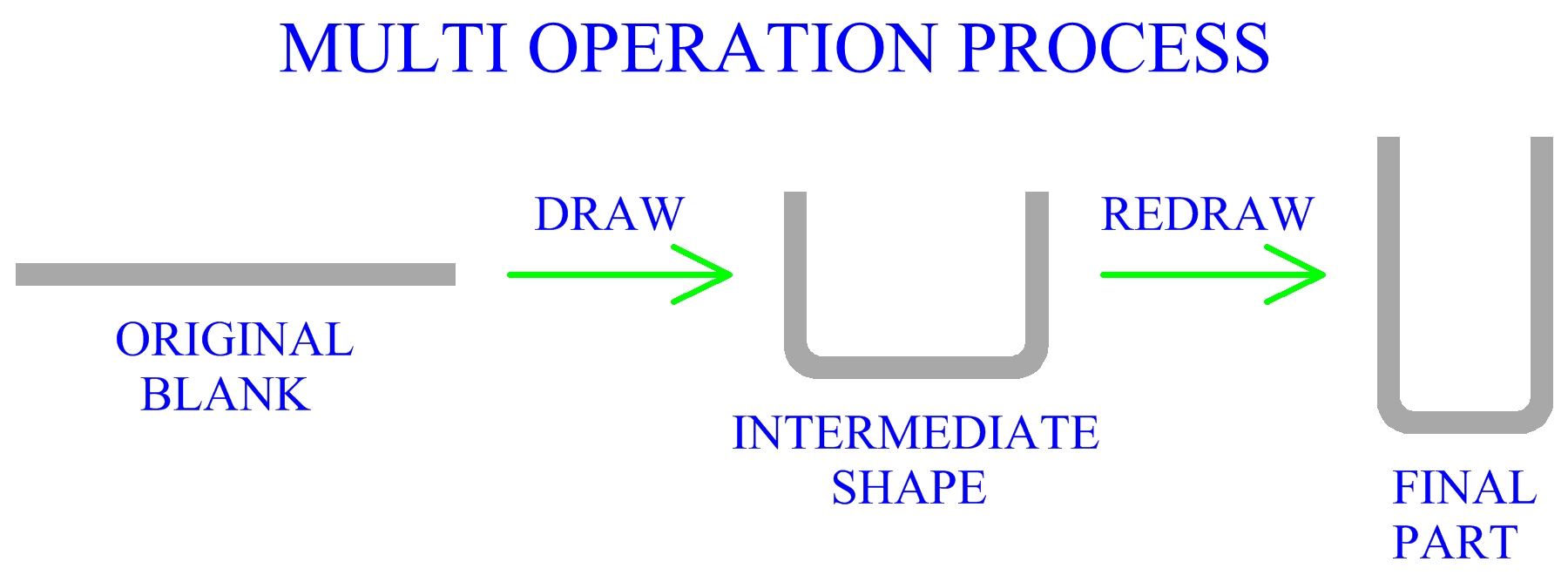

The process of deep drawing is shown in Fig. Sheet metal drawing operation is used to make A wire B tube C cup shaped parts D rods 063. A lot of deeper products can be formed with repeated deep drawing.

Drawing is a sheet-metal-forming operation used to make cup-shaped box-shaped or other complex-curved and concave parts by placing a piece of sheet metal over a die cavity and pushing the metal into the cavity with a punch. Rubber pad forming RPF is a metalworking proc ess where sheet metal is pressed between a die and a rubber block made of polyurethane. Mechanics of Deep Drawing.

True False Coining is a bulk deformation process also used in sheet-metal work in which fine. In conventional sheet metalworking operations a. For cutting sheet meatal part a combination of punching operations in various sizes and shapes rectangular and circular are used.

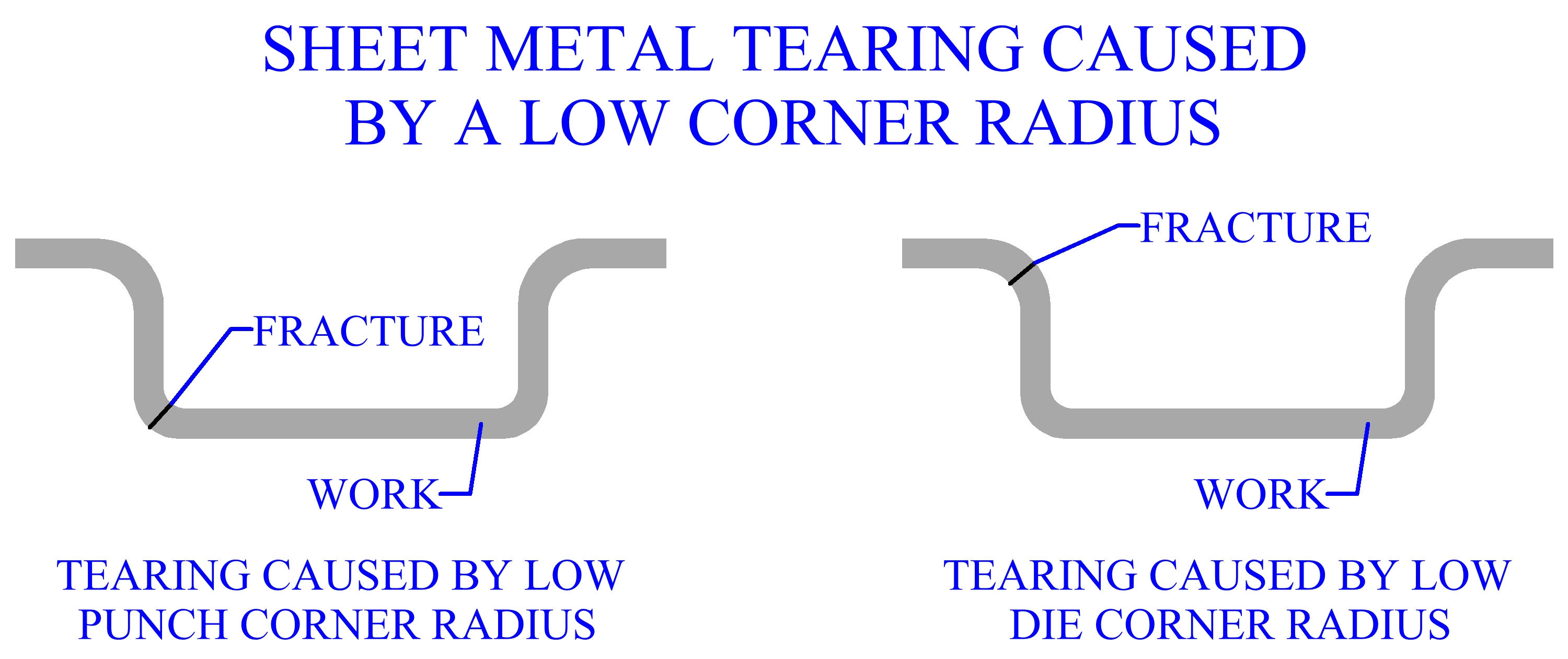

Sheet metal drawing is defined as a plastic deformation over a curved axis. A true or b false. When a metal blank is drawn into a die a change in its shape is brought about by forcing the metal to flow on a plane parallel to the die face with the result that its thickness and surface area remain about the same as the blank.

Drawing is accomplished by placing a piece of sheet metal over a die cavity and then using a. Just go through. Drawing is classified into two types.

Under pressure the rubber and sheet metal are driven into the die and conform to its shape forming the part. The stripper ring facilitates the removal of the formed cup from the punch. As the metal is drawn pulled it stretches thinner into a desired s.

3 If the ratio of height to diameter of the product is greater than 05 then this drawing operation is known as deep drawing. Usually the coils used range from 7 to 20 gauges. In Deep drawing operation when the force is applied by using the punch the sheet is simply pulled into the die without any shearing action and taking the shape and size same as that of the die.

The process is best suitable for complex shaped problems. Press brake or Brake Press in sheet metal parts utilizes v-types of flat punch and die to make straight sheet-metal bend at required angles. Drawing is a metalworking process which uses tensile forces to stretch metal or glass.

The punching operation removes the scrap material from the larger pieces of sheet metal stock by applying high shearing force. 5 Types of Dies used in Sheet Metal Operations PDF Hello guys we had discussed Press working Operations in the previous post. The punch-die clearance is slightly larger than the thickness of the sheet metal to be deep drawn.

What is the name of the tooling and b what is the name of the machine tool used in the operations. Beverage cans ammunition shells automobile body panels. Which of the operations are likely.

Sheet metal drawing and wire bar and tube drawing. FIGURE 30 The metal-forming processes involved in manufacturing a two-piece aluminum beverage can. The mechanics of deep drawing process is shown in Fig.

B Process variables in deep drawing. Sheet Metal Cutting using Punching Operation. The tooling is called a punch and die b the machine tool is called a.

In a sheet-metal-cutting operation used to produce a flat part with a hole in the center the part itself is called a blank and the scrap piece that was cut out to make the hole is called a slug. Terms in this set 19 Identify the three basic types of sheet metalworking operations. The punch is the desired shape of the base of the part once drawn.

The rubber pads can have a general purpose shape like a membrane. Sheet metal is used in various products like machinery building roofs car bodies airplanes and much more. As the load applied through the punch the sheet metal is forced to flow radially and sink into the die cavity to form a cup.

Sheet metal operations are mostly termed cold metal operations without heat or fire like shearing and cutting with the use of guillotine and saw punching to form metal parts like spoons and forks in a press drilling holes by means of drill bits in a drill press grinding and sa. In drawing operation metal flows from one place to other to give the required shape.

Sheet Metal Tools Cutting Marking Bending Tools

Deep Drawing Metallurgy For Dummies

9 Different Types Of Sheet Metal Operations With Diagram Pdf

Sheet Metal Forming An Overview Sciencedirect Topics

Deep Drawing An Overview Sciencedirect Topics

Deep Drawing Openlearn Open University

Sheet Metal Forming Processes And Equipment Machinemfg

Deep Drawing Find Suppliers Processes Material

Deep Drawing An Overview Sciencedirect Topics

Sheet Metal Forming Basics Processes And Material Used